Research

Here in the Wilker Lab, we focus on using both synthetic biomimics and naturally occurring materials to create strong adhesives and coatings for a variety of applications.

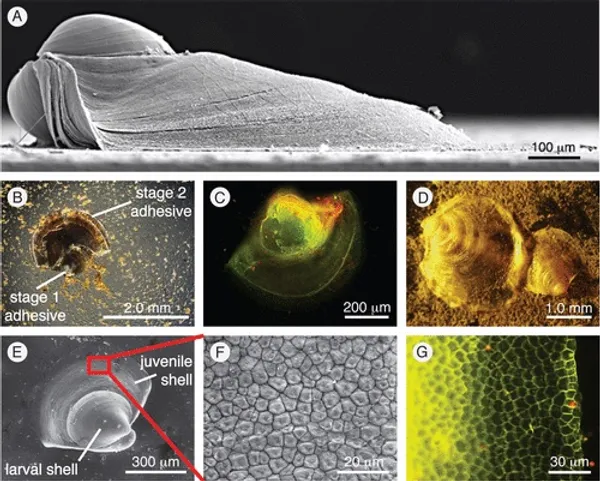

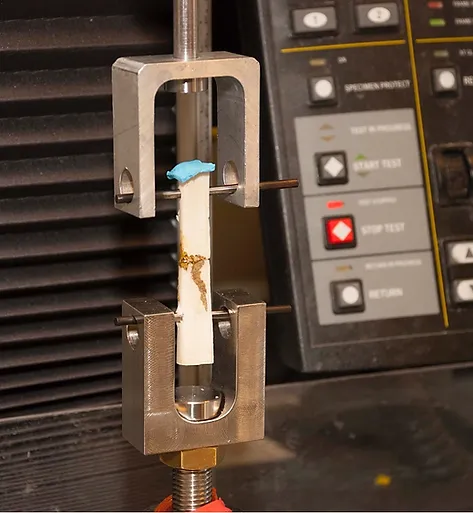

Characterization of Adhesives and Cements From Shellfish

Oysters build reef communities with an inorganic cement that bonds the animals together. Mussels make an organic adhesive when attaching to their neighbors and rocks. We are working to characterize the mechanics and composition of these adhesive materials. Methods used here include microscopy, spectroscopy, biochemical techniques, mechanical testing, and changing the environments around the animals.

Biomimetic Polymers and Materials

As we learn how nature makes materials, this information can be used to create new, biomimetic systems. Rather than making exact copies of natural systems, we use the chemistry of shellfish to create materials with properties not seen before. Complex proteins can be simplified to synthetic polymers containing key adhesion chemistry. We now have access to biomimetic adhesives that can bond substrates completely underwater. Structure-function studies help us to understand specific aspects of polymer design that bring about varied aspects of performance. Target properties may be derived from long-term goals including biomedical bonding, adhesives that can debond, and materials sustainability.

Biomedical Adhesives and Sealants

Sutures, staples, and screws are mechanical approaches to connecting tissues, creating problems including making holes, concentrating mechanical stresses, and forming sites for infection. Patient outcomes will improve when we have access to adhesives that can cure in wet environments, create strong bonds, and be non-toxic. We are using biomimetic adhesives to seal wounds and make joints between hard or soft tissues.

Sustainably Sourced Adhesives

Adhesives hold together our electronics, cars, furniture, walls, and packaging. Although modern, petroleum-based adhesives are high-performance and low-cost, these materials create several environmental problems. The adhesives do not degrade, bonds are permanent, substrates cannot be separated for recycling, and toxicity is a persistent concern. Moving toward a sustainable materials economy requires new adhesives that are high-performance, low-cost, and made from components that are already available at train car scales. We are developing sustainable adhesives systems from bio-based compounds including plant proteins, vegetable oils, small molecules, and naturally occurring phenolics. Biomimetic chemistry, inspired by shellfish adhesives, is key to achieving the needed performance. Goals for these new systems include being as strong as commercial glues, low cost, and having minimal carbon footprints.

We thank the following organizations for financial support of this work: