Hydrogen fuel cell research featured at Indiana Statehouse

2011-04-21

Professor P.V. Ramachandran joined Purdue students and faculty researchers in Indianapolis for Purdue Day at the Indiana Statehouse.

Ramachandran and his research team are collaborating with engineers at General Atomics to create safe and efficient pellets to power hydrogen fuel cells that can run an array of portable electronic devices.

The marble-sized fuel pellets, which contain a solid compound that gives off hydrogen when heated, overcome the historic challenges in using hydrogen as a fuel, said Ramachandran.

"Hydrogen gas takes up a lot of space, is unstable and unsafe to transport," Ramachandran said. "We've developed a way to use a very stable and safe compound that can release pure hydrogen gas on demand without any toxic or corrosive byproducts."

The chemical compound, which is a derivative of ammonia borane, contains many hydrogen molecules locked into a safe, compact and highly portable material, he said.

"It is like a compressed digital file you might use to send a big document in an e-mail," Ramachandran said. "It is quick and easy to send, and the recipient just clicks it open to access the transported information. The pellets actually contain four times more hydrogen atoms by volume than hydrogen gas, so it is a very efficient process."

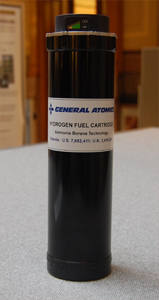

The pellets are incorporated into cartridges about the size of a small, thin soda can that simply snap into existing hydrogen fuel cells that create electric power from hydrogen gas.

The technology was commissioned to replace the battery packs used by soldiers, said Paul Clark, manager of advanced power systems for General Atomics.

"Soldiers can carry as much as 20 pounds of batteries, and this new fuel cell system reduces the weight necessary for the same amount of power by more than half," Clark said. "This also appears to be a more cost-effective energy technology that we predict will be cheaper than batteries. Our estimates translate into a potential savings of $27 million per year if it is adopted by the U.S. military."

The cost savings are due in part to a novel manufacturing method developed by Ramachandran, for which Purdue has a patent pending.

"This manufacturing method significantly reduces the costs to produce the compound from around $2 per gram to around 10 cents per gram," he said. "The pellets also can be recharged to produce more hydrogen fuel."

Currently the compound is made in Ramachandran's laboratory in small quantities and is then sent to General Atomics, where it is pressed into pellets and put into cartridges.

The production process needs to be scaled up in order for the technology to be useful, and locations in Indiana are being considered for a manufacturing facility, Clark said.

Ramachandran next plans to study the potential for the compound to be used as fuel for hydrogen-powered cars.

"I think this technology could be used for a wide variety of everyday applications from recharging your cell phone to powering your laptop and perhaps one day your car," he said. "Many of the technologies we take for granted in our everyday lives were originally created for military or space exploration purposes."

Photo from left to right: Dr. Pravin Gagare (Ramachandran Group researcher), Dr. Paul Clark (General Atomics), Professor P.V. Ramachandran.

Source: Purdue Chemistry/University News Service

P.V. Ramachandran

Professor Organic Chemistry