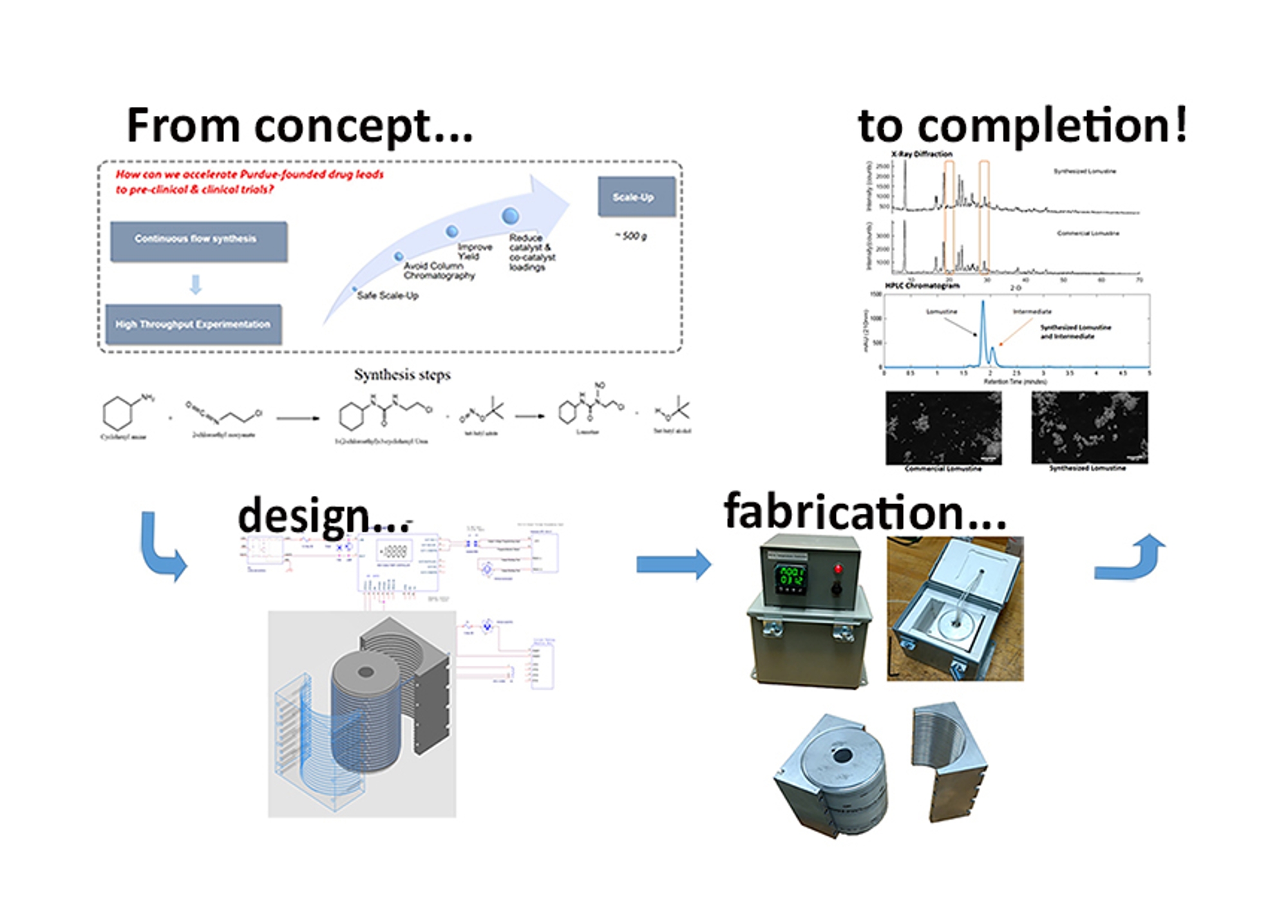

Coiled Tubing Reactor

"You dream it, we build it together!" This coiled tubing reactor for the Nagy and Thompson groups follows a concept through design, fabrication, testing and completion. This reactor became a part of the first continuous manufacturing process for an anti-cancer agent.

Continuous flow synthesis is an emerging method of chemical synthesis in which compounds are synthesized in a continuously flowing liquid stream as opposed to traditional large volume batches. Continuous flow synthesis takes advantage of various smaller scale phenomena and is highly amenable to automation, making it attractive as a production method for active pharmaceutical ingredients. Prof. David Thompson’s group develops flow chemistry methods and studies the relationships between flow chemistry techniques and traditional batch synthesis methods. Zoltan Nagy’s group in Chemical Engineering develops methods for crystallization (purification) of compounds using flowing systems.

Lomustine is a chemotherapy drug used to treat brain tumors, lymphomas, and other cancers. Lomustine experienced a dramatic price increase in 2013 after its US patent expired and the brand was sold to a new producer. Development of new lomustine production methods is therefore of vital importance as a mechanism for creating competition in order to drive down prices for patients. Together, the Thompson and Nagy groups have developed an end-to-end continuous flow synthesis and purification method for the production of lomustine. As part of their effort to scale up the process, they required a temperature controlled flow reactor of larger volume. That’s when they turned to the Amy Facility.

We designed and built a flow reactor involving a coil of tubing enclosed within a heated aluminum block. Unlike traditional temperature control schemes that rely on a relay to cycle power to the heater, this design uses a voltage controlled DC power supply to continuously vary the heater power. The reactor and associated electronics are combined in a single unit for operator convenience. Ryan Hilger and Cathy McIntyre of the Amy Facility, Randy Replogle of the Precision Machine Shop, and Jaron Mackey of the Nagy group collaborated to create the coiled tubing reactor. Application of the coiled tubing reactor to lomustine synthesis was performed by Jaron Mackey of the Nagy group along with Ahmed Mufti of the Thompson group.

- A Look Inside the Amy Facility

- 8-Channel RF Signal Generator

- Apple Pencil Charger

- Photochemical Reactor

- RCF Controller

- High Bandwidth 16-Channel PMT Amplifier

- Microsecond Raman imaging might probe cells, organs for disease

- O'Buoy Project

- ALAR

- Argos Data Collector

- Vertical Air Profiler

- Triboluminescence

- Flow Reactor

- TRAC

- E-Beam Project

- Coiled Tubing Reactor

- Carbon Fiber Tubing

- Cryogenic Cooling Stage

- Photomultiplier Tube Power Supply

- Cold Ion Spectroscopy

- Mass Spec Solids Probe

- Spherical Void Electrodynamic Levitator

- Linear Rail Fatigue Tester

- Florescence Imaging System

- Pulse Stretching Amplifier

- Modular Low-Cost Photoreactor Chamber

- Hot Plate Photoreactor