Photochemical Reactor

In certain photochemical transformations in solid-phase synthesis it is desirable to irradiate a sample while under continuous agitation in order to selectively break chemical bonds within a homogenous mixture. These bonds are wavelength specific, and the solvents that the mixture are suspended in are temperature sensitive. For these reasons, using a highly specific wavelength of light aids in keeping total system energy, and therefore temperature, low, and results in higher chemical yields in less time and with lower evaporated solvent.

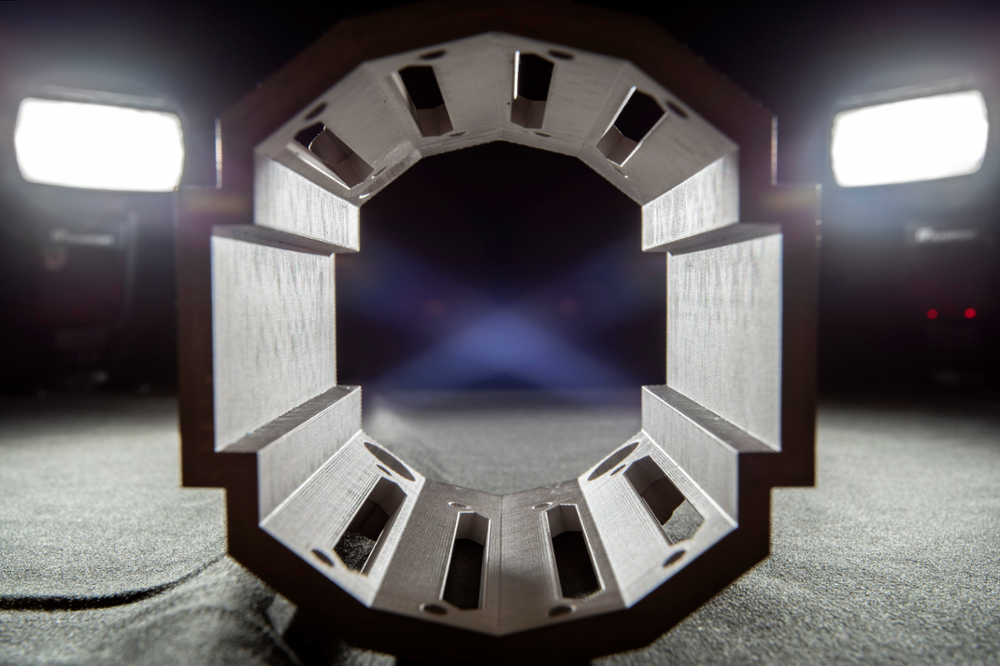

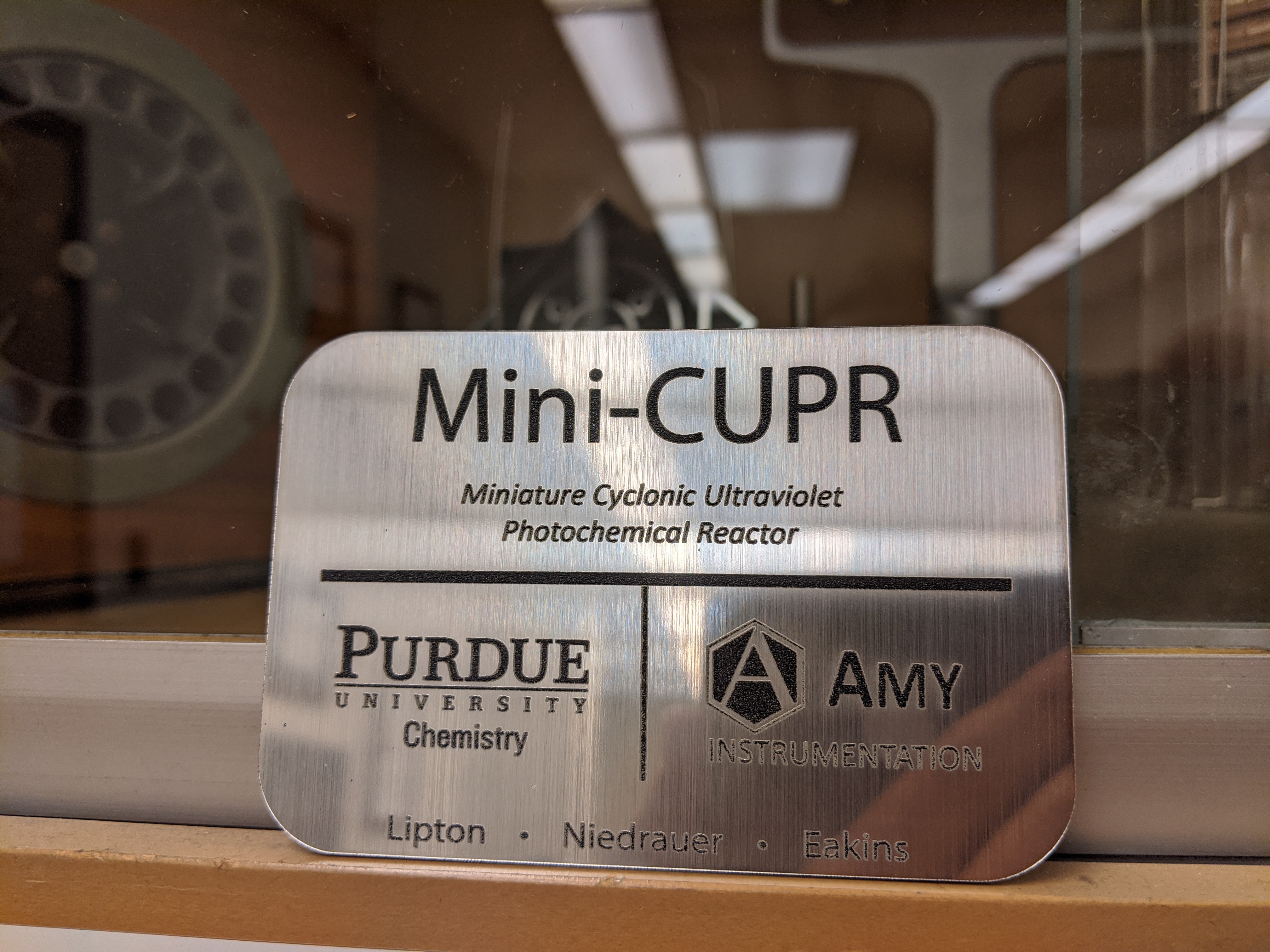

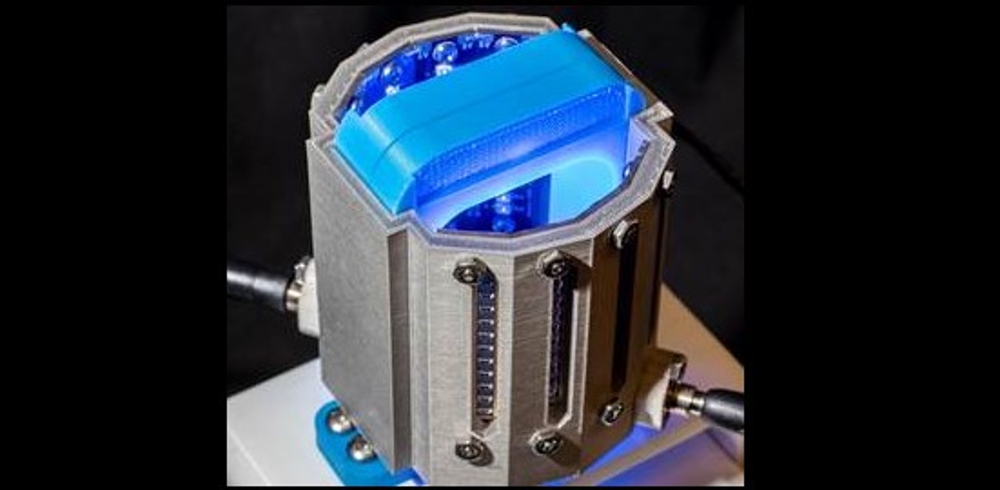

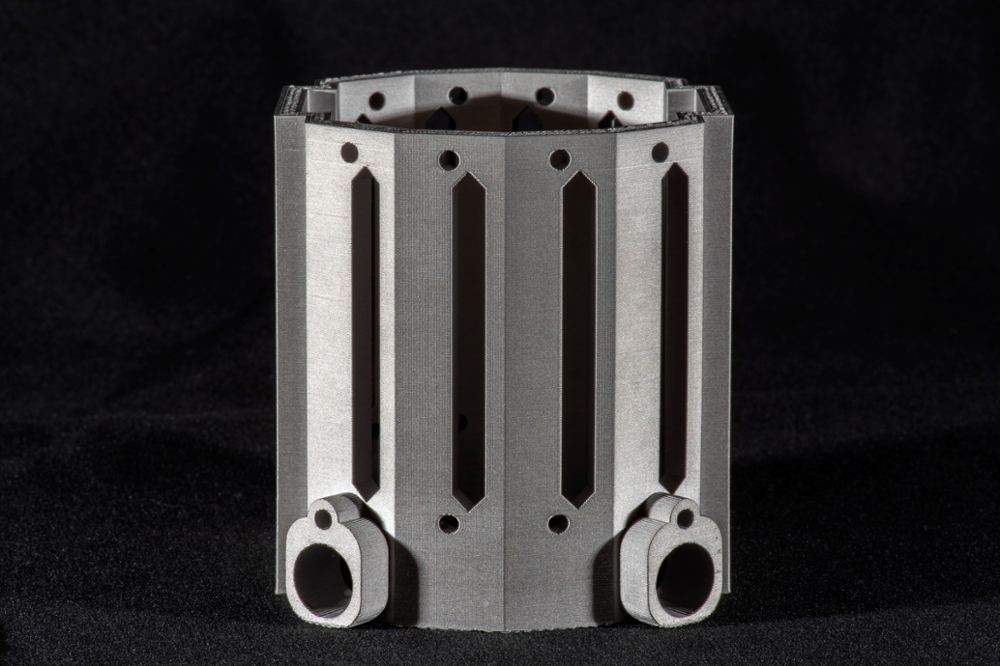

The Mini-CUPR (Miniature Cyclonic Ultraviolet Photochemical Reactor) was developed to meet these specific needs. The system is mounted on top of a standard vortex mixer and consists of a frame to loosely hold the vial while being shaken by the vortex mixer, and a custom designed stainless-steel chamber printed out of stainless steel on our in-house metal 3D printer. The printed circuit boards (PCBs) hold 96 LEDs that output 365nm light onto the sample. The PCBs are specially designed to pull heat generated by the LEDs to the outside of the chamber and conduct it into the metal outer chamber to keep inner chamber temperatures cool.

| Research Group: | Mark Lipton, Chemistry |

| Lab Contact: | Miri Niedrauer, Chemistry |

| Amy Contact: | Greg Eakins, Chemistry |

- A Look Inside the Amy Facility

- 8-Channel RF Signal Generator

- Apple Pencil Charger

- Photochemical Reactor

- RCF Controller

- High Bandwidth 16-Channel PMT Amplifier

- Microsecond Raman imaging might probe cells, organs for disease

- O'Buoy Project

- ALAR

- Argos Data Collector

- Vertical Air Profiler

- Triboluminescence

- Flow Reactor

- TRAC

- E-Beam Project

- Coiled Tubing Reactor

- Carbon Fiber Tubing

- Cryogenic Cooling Stage

- Photomultiplier Tube Power Supply

- Cold Ion Spectroscopy

- Mass Spec Solids Probe

- Spherical Void Electrodynamic Levitator

- Linear Rail Fatigue Tester

- Florescence Imaging System

- Pulse Stretching Amplifier

- Modular Low-Cost Photoreactor Chamber

- Hot Plate Photoreactor