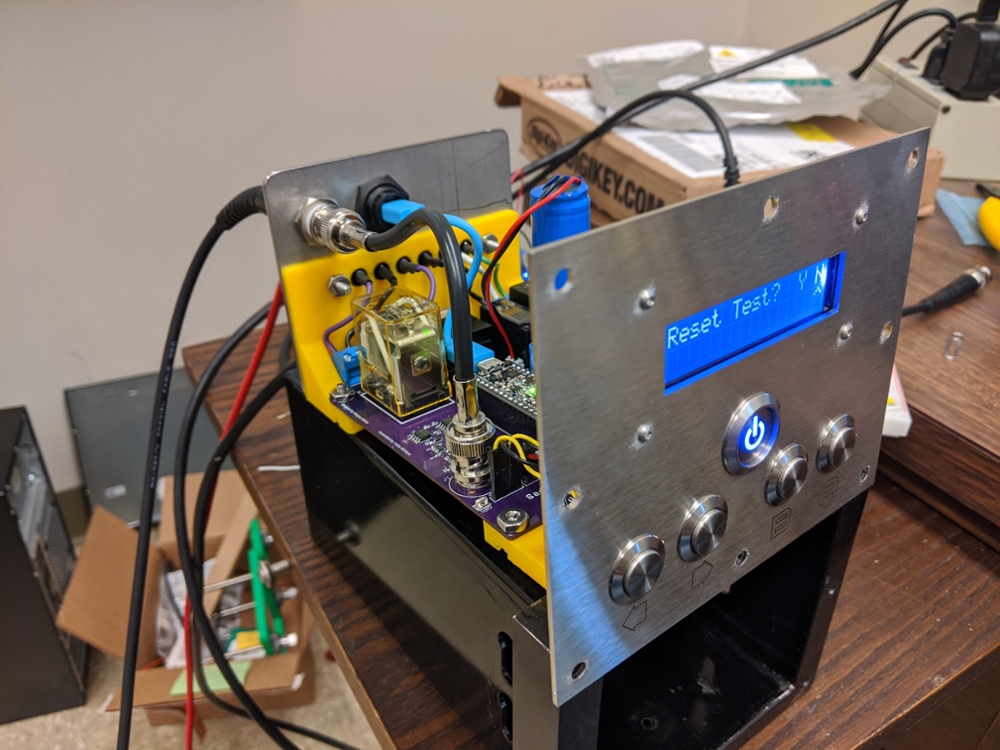

RCF Controller

A Rolling Contact Fatigue (RCF) apparatus induces complex subsurface stress states in bearing steel materials. This produces significant microstructural alterations and fractures within the material that can be studied for classification and improvement anywhere that bearings are used.

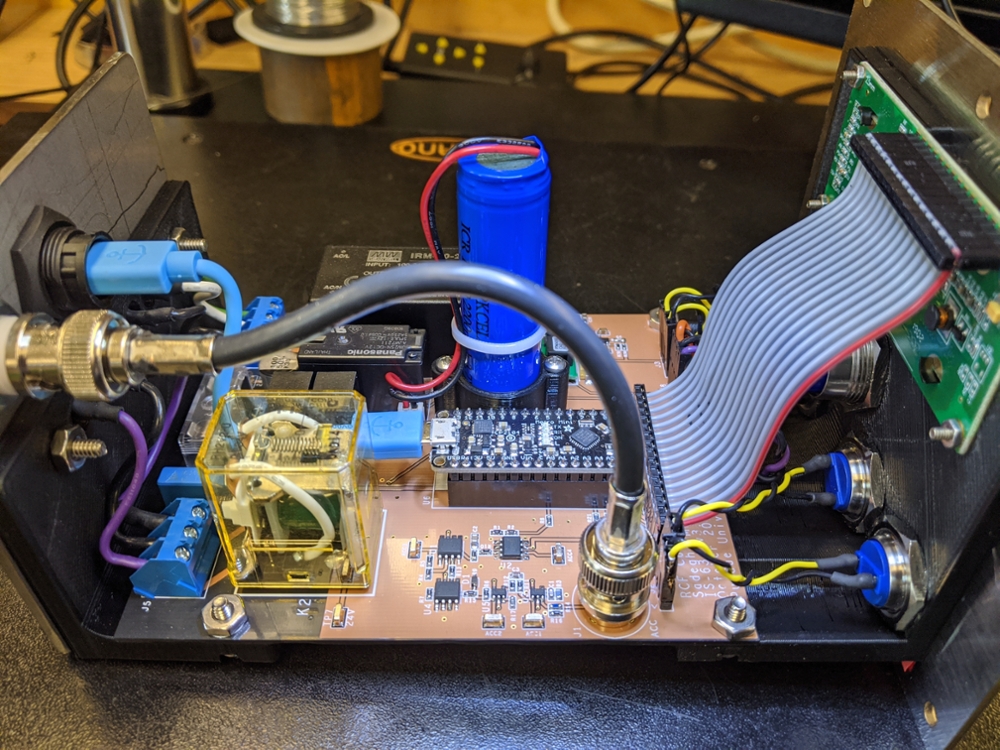

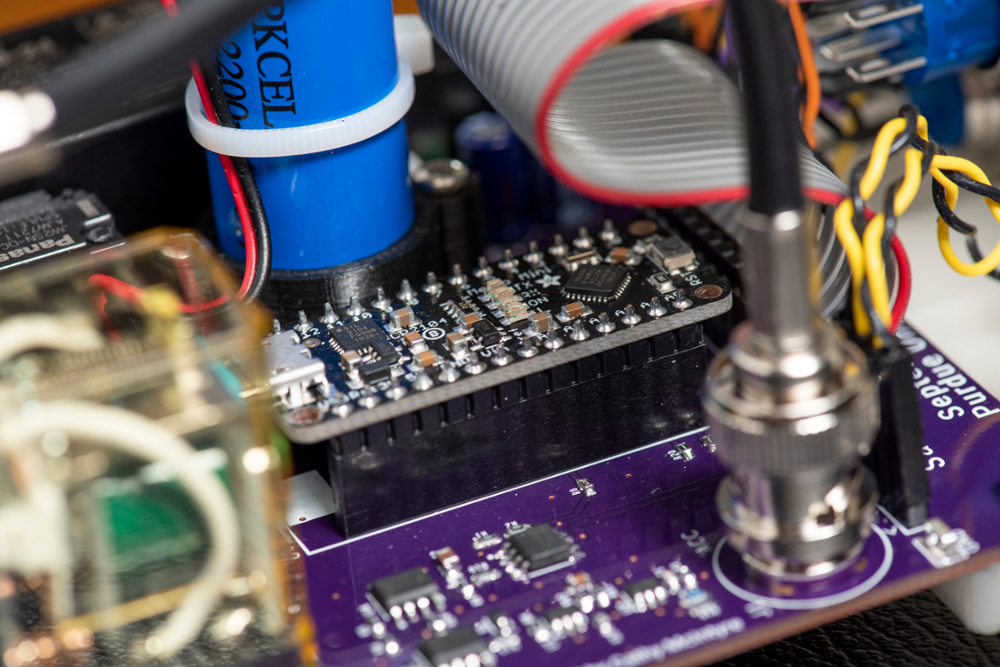

This RCF apparatus replaces and improves a nearly 50 year old analog system that was starting to fail. The new system works by controlling a bearing drive motor and continuously monitoring the vibration levels (calculated through an analog integration of raw piezoelectric sensor readings) present on a rotating sample and triggers immediately when a user-programmable stop condition is met. Time to failure is then displayed to the user. This particular system features a battery backup that pauses the test and allows the user to resume the test when power is restored. This is particularly helpful, as the tests can run 30 days or more before failure.

| Research Group: | Farshid Sadeghi, Mechanical Engineering |

| Lab Contact: | Dallin Morris, Mechanical Engineering |

| Amy Contact: | Greg Eakins, Chemistry |

- A Look Inside the Amy Facility

- 8-Channel RF Signal Generator

- Apple Pencil Charger

- Photochemical Reactor

- RCF Controller

- High Bandwidth 16-Channel PMT Amplifier

- Microsecond Raman imaging might probe cells, organs for disease

- O'Buoy Project

- ALAR

- Argos Data Collector

- Vertical Air Profiler

- Triboluminescence

- Flow Reactor

- TRAC

- E-Beam Project

- Coiled Tubing Reactor

- Carbon Fiber Tubing

- Cryogenic Cooling Stage

- Photomultiplier Tube Power Supply

- Cold Ion Spectroscopy

- Mass Spec Solids Probe

- Spherical Void Electrodynamic Levitator

- Linear Rail Fatigue Tester

- Florescence Imaging System

- Pulse Stretching Amplifier

- Modular Low-Cost Photoreactor Chamber

- Hot Plate Photoreactor